please enter your keyword

NCC / ECC

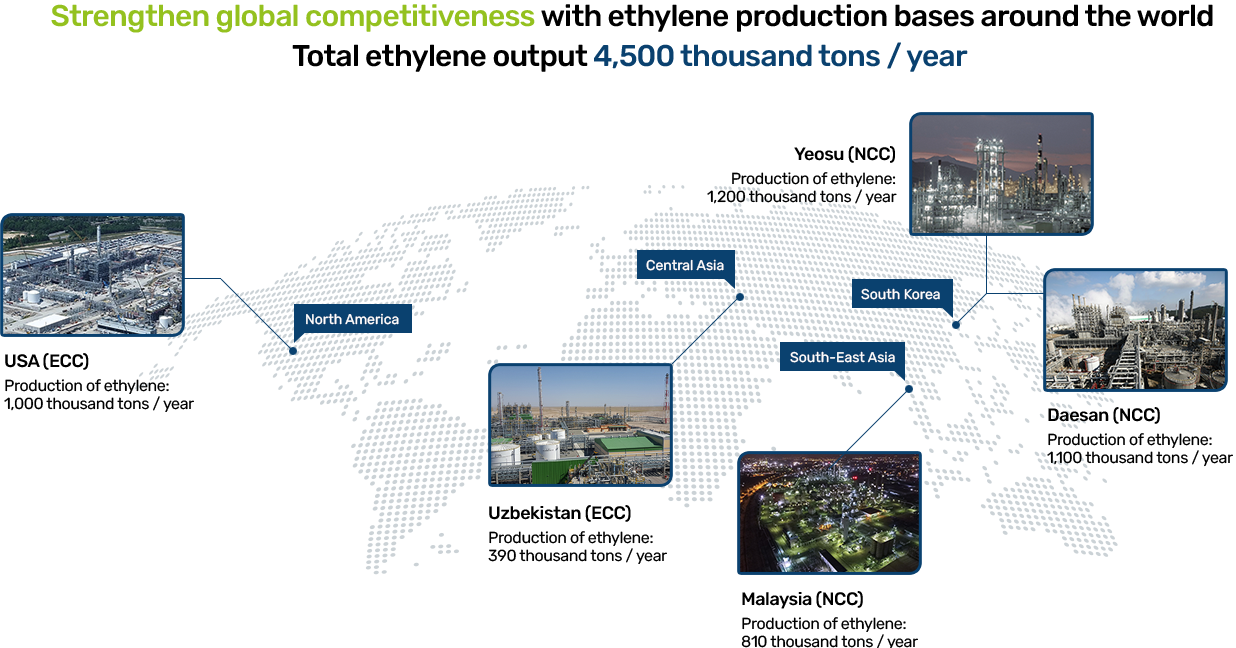

NCC is used to produce raw materials for various products including ethylene, known as the key building block for many industries. LOTTE Chemical’s high competitiveness is achieved by diversification of raw materials and expansion of global production bases.

NCC / ECC (Naphtha Cracking Center / Ethane Cracking Center)

Chemical products produced by LOTTE Chemical is derived from naphtha, which is obtained by refining crude oil. The Naphtha Cracking Center(NCC) pyrolyzes naphtha at ultra-high temperature of more than 1,200°C to produce major products such as ethylene, propylene and

byproducts such as mixed C4 and pyrolysis gas. Through stable operation of plants and continuous expansion in production capacity, LOTTE Chemical has built a globally competitive manufacturing facility.

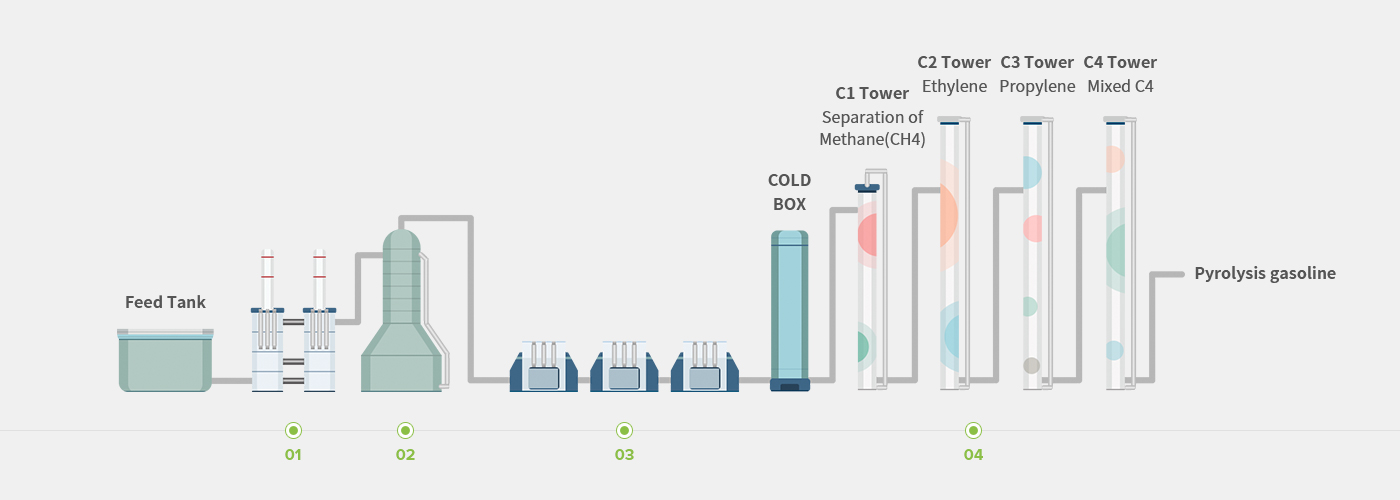

Plant Process

-

Thermal Cracking ProcessNaphtha, a raw material, goes through thermal cracking at high temperature of over 1000°C and is separated into hydrocarbon compounds with various components. Hydrogen, methane, and C4LPG produced from the process are used as fuel.

-

Quenching ProcessThe substance that is thermally cracked in the cracker is quenched to prevent coke and tar formation and to separate medium crude oil(thermally cracked fuel oil, thermally cracked gas). The substance goes through a second quenching process in the quench tower to produce thermally cracked gasoline, which is supplied to the BTX plant as raw material. The separated light cracked gas is sent to the compression process.

-

Compression ProcessThe quenched cracked gas is compressed under high pressure (38KG) that enables economical separation.

-

Refining ProcessThe compressed and dried cracked gas is cooled to -167°C in the cold box. The cracked gas is then separated as it goes through the distillation tower, reactor, absorption tower and rectifying tower.

Applications

Raw materials for various synthetic resins, synthetic fibers (polyester fiber), synthetic rubbers, etc.

Key Features

Leading basic raw materials in the petrochemical industry A C2-based olefine hydrocarbon, which is a colorless gas slightly lighter than air at normal temperature and pressure

Specifications

| Test Item | Unit | Test Method | Specification |

|---|---|---|---|

| Ethylene | MOL.% | G.C | MIN 99.9 |

| Methane & Ethane | MOL.PPM | G.C | MAX 500 |

| Acetylene | MOL.PPM | G.C | MAX 5 |

| Water(H2O) | WT.PPM | PANAMETRICS | MAX 5 |

| Carbon Monoxide | MOL.PPM | G.C | MAX 5 |

| Carbon Dioxide | MOL.PPM | G.C | MAX 5 |

| Oxygen | MOL.PPM | G.C | MAX 5 |

| Sulfur(H2S) | WT.PPM | ASTM D3246 | MAX 2 |

| C3 & Heavier | MOL.PPM | G.C | MAX 5 |

| Hydrogen | MOL.PPM | G.C | MAX 5 |

| Methanol | MOL.PPM | G.C | MAX 5 |

Applications

Raw materials for various synthetic resins, synthetic fibers, synthetic rubbers, etc.

Key Features

A C3-based olefine hydrocarbon, which is a colorless gas slightly lighter than air at normal temperature and pressure

Specifications

| Test Item | Unit | Test Method | Specification |

|---|---|---|---|

| Propylene | MOL.% | G.C | MIN 99.6 |

| Propane | MOL.% | G.C | MAX 0.45 |

| Carbon Dioxide | MOL.PPM | G.C | MAX 5 |

| Carbon Monoxide | MOL.PPM | G.C | MAX 5 |

| Oxygen | MOL.PPM | G.C | MAX 5 |

| Ethane | MOL.PPM | G.C | MAX 200 |

| Ethylene | MOL.PPM | G.C | MAX 100 |

| Acetylene | MOL.PPM | G.C | MAX 5 |

| cyclo-Propane | MOL.PPM | G.C | MAX 5 |

| Methanol | MOL.PPM | G.C | MAX 20 |

| Sulfur(H2S) | WT.PPM | ASTM D3246 | MAX 2 |

| Water | WT.PPM | PANAMETRICS | MAX 5 |

| MA + PD | MOL.PPM | G.C | MAX 5 |

| C4's | MOL.PPM | G.C | MAX 5 |

Applications

Raw material for the BD manufacturing process

Key Features

A C3-based hydrocarbon mixture, which is a colorless gas lighter than air at high temperature and pressure

Specifications

| Test Item | Unit | Test Method | Specification |

|---|---|---|---|

| 1,3-Butadiene | wt% | TS-AE-E15-746 | MIN 32.5 - MAX 56.3 |

| C3 & Lighter | wt% | TS-AE-E15-746 | MAX 0.20 |

| n-Butane + i-Butane | wt% | TS-AE-E15-746 | REPORT |

| 1-Butene | wt% | TS-AE-E15-746 | REPORT |

| i-Butene | wt% | TS-AE-E15-746 | REPORT |

| Trans-2-Butene | wt% | TS-AE-E15-746 | REPORT |

| Cis-2-Butene | wt% | TS-AE-E15-746 | REPORT |

| Methyl Acetylene | wt% | TS-AE-E15-746 | REPORT |

| 1,2-Butadiene | wt% | TS-AE-E15-746 | REPORT |

| Ethyl Acetylene | wt% | TS-AE-E15-746 | REPORT |

| Vinyl Acetylene | wt% | TS-AE-E15-746 | REPORT |

| C5 & Heavier | wt% | TS-AE-E15-746 | MAX 0.20 |

Applications

Raw material for the BTX manufacturing process

Key Features

A C5 to C10-based hydrocarbon liquid mixture with hydrocarbon odor

Specifications

| Test Item | Unit | Test Method | Specification |

|---|---|---|---|

| Benzene | WT.% | G.C | REPORT |

| Toluene | WT.% | G.C | REPORT |

| Sulfur | WT.PPM | TS-AE-E15-568 | MAX 1450 |

| Bromine Number | g/100g | TS-AE-E15-567 | MAX 80 |

| Existent Gum | mg/100mL | TS-AE-E15-506 | MAX 30 |

| Density(15℃) | g/mL | ASTM D4052 | REPORT |

| Distillation | ℃ | TS-AE-E15-509 | |

| I.B.P | MIN 36 | ||

| 90% | REPORT | ||

| E.P | MAX 200 | ||

| Vapor Pressure(Reid) | psi | TS-AE-E15-512 | MAX 13 |

| Water | WT.PPM | TS-AE-E15-561 | MAX 500 |

| C5'S | WT.% | G.C | REPORT |

| Non-aromatic | WT.% | G.C | REPORT |

| Ethylbenzene | WT.% | G.C | REPORT |

| Styrene | WT.% | G.C | REPORT |

| o-Xylene | WT.% | G.C | REPORT |

| p,m-Xylene | WT.% | G.C | REPORT |

| Xylenes | WT.% | G.C | REPORT |

| C4's & Lighter | WT.% | G.C | REPORT |

| Total Aromatics | WT.% | G.C | REPORT |

| C9 Aromatics | WT.% | G.C | REPORT |

| C10 Aro | WT.% | G.C | REPORT |

| C10 NA | WT.% | G.C | REPORT |

| DV | g/100g | UOP 326 | REPORT |

| C9 & Heavier | WT.% | G.C | REPORT |

TOP